Ensemble de revêtement de revêtement en poudre de tôle personnalisée

Obtenir le dernier prix| Type de paiement: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Quantité de commande minimum: | 1000 Piece/Pieces |

| transport: | Ocean |

| Hafen: | Jiangmen,Shenzhen,Guangzhou |

| Type de paiement: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Quantité de commande minimum: | 1000 Piece/Pieces |

| transport: | Ocean |

| Hafen: | Jiangmen,Shenzhen,Guangzhou |

Modèle: DJ-WIL-138

marque: Dongji

Lieu D'origine: Chine

Size: Custom

Custom Package: Yes

Furface Finishing: Powder coating

Qualification: CE,UL, ISO, TUV

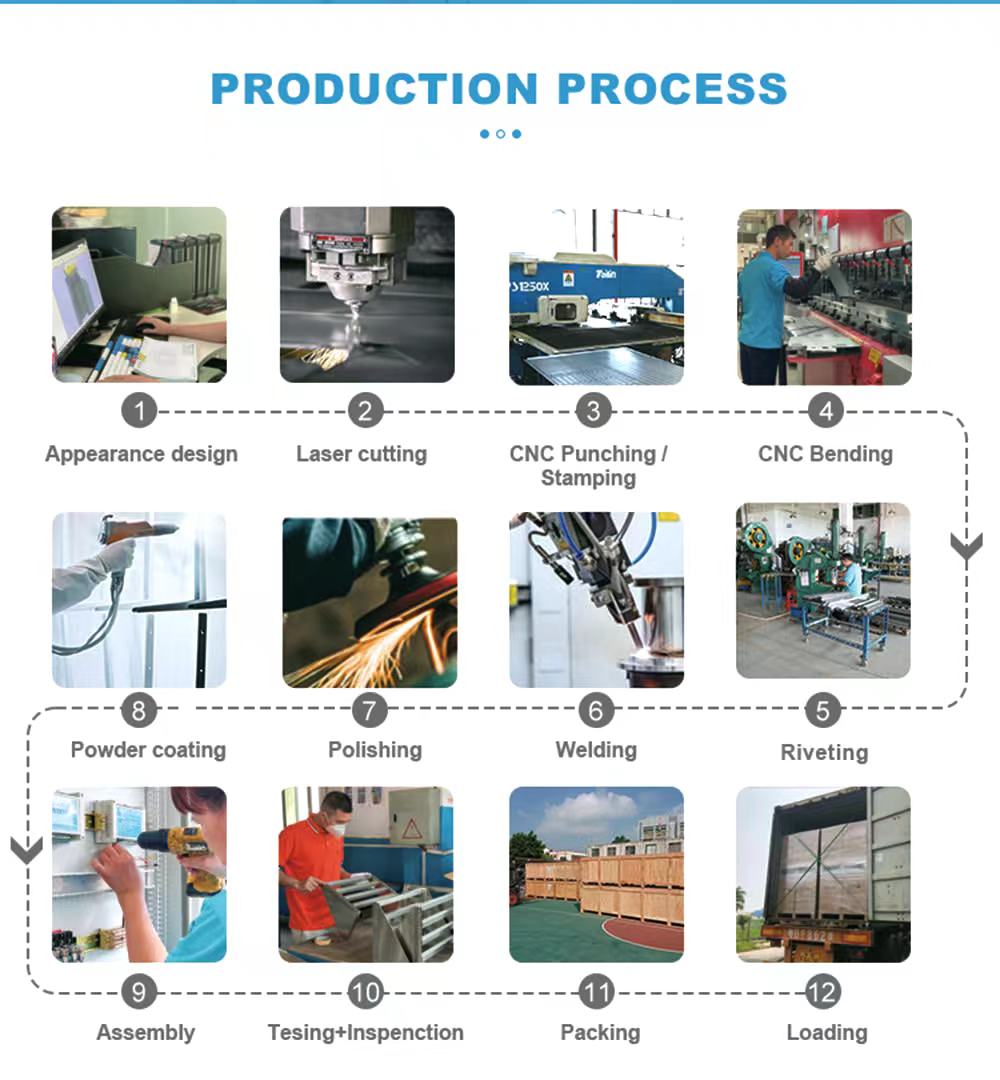

Craftmanship: Laser cutting, CNC punching, CNC bending, Laser welding, surface finishing,

Material: Mild steel

Application: EV charger

| Unités de vente | : | Piece/Pieces |

| Type de colis | : | Forfait de livraison international personnalisé ou régulier |

The file is encrypted. Please fill in the following information to continue accessing it

DONGJI has more than 200 production employees, of which about 25% are professional engineers, has more than 200 production patents, more than 38,000 square meters of workshops, and a full set of sheet metal processing equipment. We specialize in manufacturing all kinds of OEM custom metal enclosures, providing one-stop service for our customers. We can provide overall solution services according to customer needs, and reduce customer costs through overall services. With the development of global new energy vehicles, we are providing charging pile sheet metal casings for many new energy companies.

|

|

Why you can trust us?

|

| ||||||||||||||||

Que pouvons-nous faire?

|  | ||||||||||||||||

|  |

Q1. What if the custom OEM EV charging station housing are broken when we receive them?

Our products are 100% inspection before delivery. We will fix the items at our cost if we are responsible for the broken issues.Q2. What should I do if the powder coating charging pile effect can not meet my request?

Most of our mild steel items are customized. Including material, dimensions and other design. Of course we will give you some suggestions if you are not sure about the details.

Q3. How long should we take for a quotation?

We will quote you within 3 days after receiving detailed information (your 2D/3D drawings or samples.)

Q4. How about the lead time?

15 days for sample, 30 days for mass production.